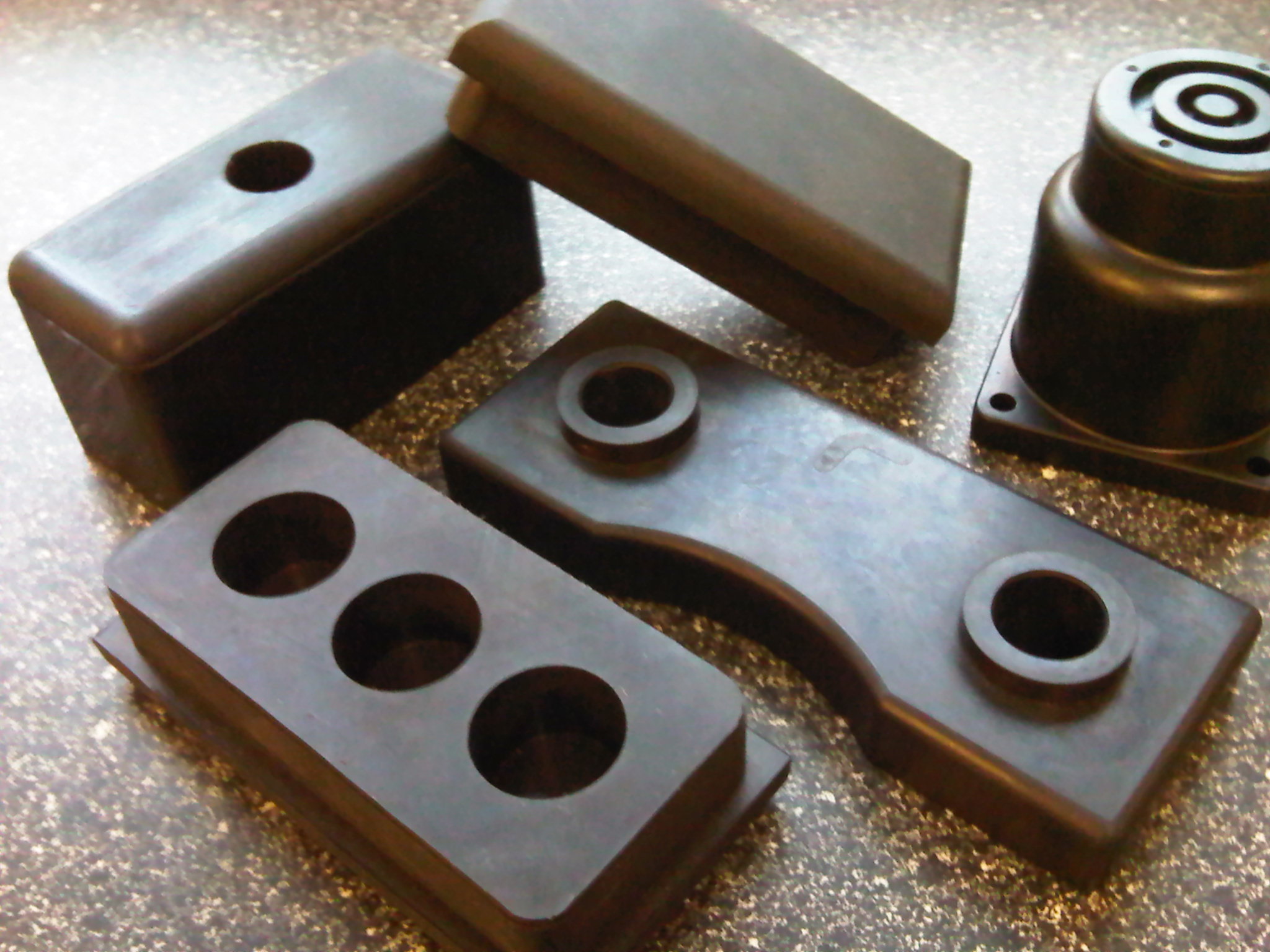

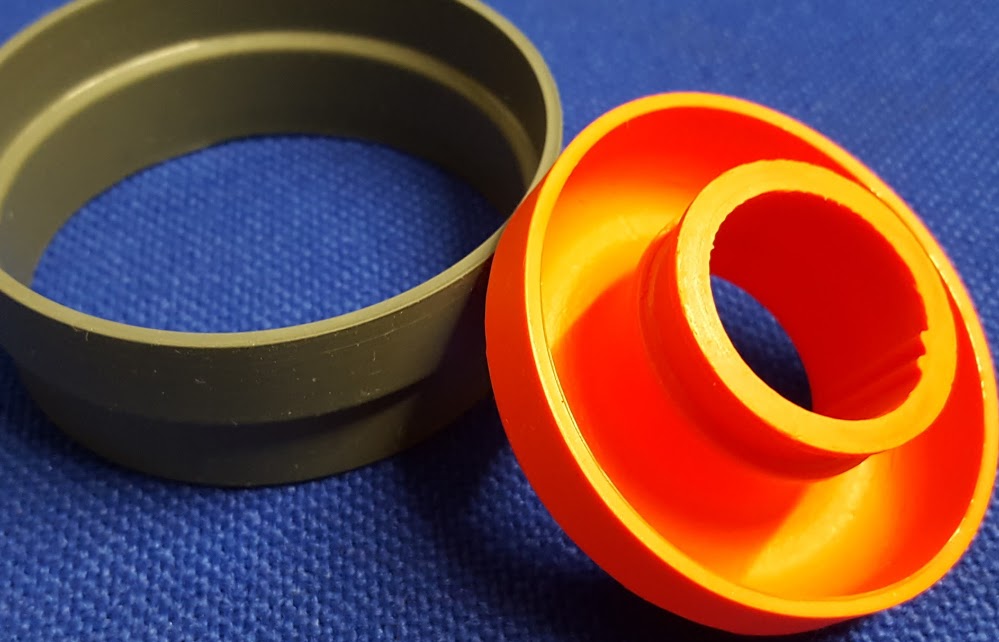

Butser Rubber manufacture mouldings, seals and gaskets from a wide range of organic and synthetic rubbers and elastomers

Materials

Please see our range of ‘Off the Shelf’ rubbers and silicones using the table below. If the material you require is not listed below, please contact our team for a quotation at enquiries@butserrubber.com

- (AEM) DuPont Vamac (Ethylene Acrylic Elastomer)

- (CR) Neoprene© & Poly-Chloroprene Rubber

- (ECO) Hydrin or epichlorohydrin rubber

- (EPDM) Ethylene Propylene Diene Monomer

- (FKM) (FPM) Viton® & flurocarbon rubbers

- (FVMQ) Fluorosilicone & fluoroelastomers

- (HNBR) (H-NBR) Hydrogenated nitrile butadiene rubber

- (IIR) Butyl Rubber

- Loaded Rubbers and Silicones

- Nitto Sponges

- (NBR) Nitrile rubber

- (NR) Natural Rubber

- (PCR) PCR rubber

- (PUR) Polyurethane rubber (Poly-U rubbers)

- (SBR) Styrene Butadiene Rubber

- Resilon slip coat and slip coatings

- (VMQ) Silicone Sponge Sheet

- (VMQ) Silicone Rubbers (Moulding Grades)

- 3M Tapes

AEM – Vamac

Vamac Engine Seals AEMDuPont Vamac® is an excellent elastomer for applications requiring superior thermal and chemical resistance. Commonly used for automotive components, Vamac provides long-term durability while exposed to chemicals over a range of temperatures. The Vamac AEM material retains its excellent sealing properties when under compression which makes it the material of choice many gasket applications. Common applications for DuPont Vamac AEM is engine and transmission seals, air ducts, connectors etc.

Stocked

- Vamac G (AEM) 60

- Vamac G (AEM) 65

- Vamac G (AEM) 70

- Vamac GF (AEM) 60

- Vamac GF (AEM) 65

- Vamac GF (AEM) 70

- Vamac LS (AEM) 60

- AEM 60 BLACK-HVG

- AEM VAMAC (ULTRA) 60 LS (LOW SMOKE)

- AEM VAMAC (ULTRA) 70 LS (LOW SMOKE)

*All Vamac is a Registered DuPont Material.

CR - Neoprene and Polychoroprene Rubber

(CR) Poly-Chloroprene and Neoprene© Rubber

Neoprene or Polychloroprene is a family of synthetic rubbers that are produced by polymerization of chloroprene. Neoprene exhibits good chemical stability, and maintains flexibility over a wide temperature range.

Stocked:

-

- Polychloroprene 40 Grey

- Polychloroprene 40 (Non ETU)

- Polychloroprene 50 Green NE

- Polychloroprene 50 (Non ETU) (C 50)

- Polychloroprene 50 Red (PCR 50)

- Polychloroprene 50 Yellow

- Polychloroprene 50-55

- Polychloroprene 55/60

- Polychloroprene 60 Ne Grey

- Polychloroprene 60 Ne Grey (RAL 7036)

- Polychloroprene 60 Non ETU. Bs2752 C60

- Polychloroprene 70 Grey (NE)

- Polychloroprene Yellow 55 Shore

- Neoprene 40 Non-Blooming (Without Wax)

- Neoprene 40 (NE CR QX40) Non TYP

- Neoprene 50 (NE CR QX40) Non TYP

- Neoprene 60 (NE CR QX60) Non TYP

- Neoprene 70 (NE CR QX40) Non TYP

- Neoprene C.40 (Non ETU)

- Neoprene C.50 To Bs2752 (Non ETU)

- Neoprene C.60 To Bs2752 (Non ETU)

- Neoprene C.80 To Bs2752 Black

- Neoprene Non ETU 76-85 Black Bs2752 C80

- Neoprene Rubber To Bs2752 C50 Black IRHD 46-55

- Neoprene Rubber To Bs2752 C60 IRHD 56-65

- Neoprene Rubber To Bs2752 C70 IRHD 66-75

- Polychloroprene Bs2752 C40 Black Neoprene

- Polychloroprene Bs2752 C60 Ne (Non ETU )

Polychloroprene Bs2752 C70 Neoprene 66-75

(ECO) Hydrin or Epichlorohydrin rubber

Stocked:

- ECO / EPICHLOROHYDRIN 40 SHORE A

- ECO / EPICHLOROHYDRIN 45/55 SHORE

- ECO / EPICHLOROHYDRIN 50 IRHD

- ECO / EPICHLOROHYDRIN 55/65 GREY

- ECO / EPICHLOROHYDRIN 60 CONDUCTIVE

- ECO / EPICHLOROHYDRIN 60 SHORE

- ECO / EPICHLOROHYDRIN 65 BLACK

- ECO / HYDRIN RUBBER 70/75

- ECO / HYDRIN RUBBER 80 IRHD

- ECO / HYDRIN RUBBER 85/95

- ECO / HYDRIN RUBBER 90 ‘SHORE A’

EPDM Rubber

(EPDM) Ethylene Propylene Diene Monomer

EPDM is available as a copolymer (EPR) or as a terpolymer (EPDM). These elastomers have excellent resistance to heat, water, steam, weathering and ozone, and are widely used in the automotive industry.

Stocked

- EPDM 20/25 Black

- EPDM 40 Shore

- EPDM 40/45 Black

- EPDM 50 Automotive Grade – Burn test to ISO3795 FMVSS 302

- EPDM 50 Rubber – Insulative Black

- EPDM 60 Grey

- EPDM 60 Automotive Grade – Burn test to ISO3795 FMVSS 302

- EPDM 60 Bright Red

- EPDM 60 Peroxide

- EPDM 60 Blue (FDA and Metal Detectible).

- EPDM 65/75 Black

- EPDM 65/75 Pillar Box Red

- EPDM 70 Shore

- EPDM 70 Black Insulative

- EPDM 70 Red

- EPDM 70 Automotive Grade – Burn test to ISO3795 FMVSS 302

- EPDM 70 Bright White

- EPDM 70 White FDA Approved

- EPDM 70 Black (Water Council Type)

- EPDM 70 White FDA Compliant

- EPDM 70 Grey (Non Marking Grade)

- EPDM 70 Blue (FDA and Metal Detectible)

- EPDM 75 Automotive Grade – Burn test to ISO3795 FMVSS 302

- EPDM 80 Automotive Grade – Burn test to ISO3795 FMVSS 302

- EPDM 80 Peroxide DTD 5597A

- EPDM 80 DTD5597A Grade 80 Black

- EPDM 80/85 FDA Aqueous

- EPDM/SBR 80 Black

- EPDM 80 High ENB.

- EPDM 90 Automotive Grade – Burn test to ISO3795 FMVSS 302

FKM, Viton and FPM

(FKM) (FPM) Fluorocarbon and Viton® rubber.

Fluorocarbon elastomers are highly fluorinated carbon-based polymers and rubber used in applications to resist harsh chemical, temperature and ozone attack.

Stocked:

- FKM 40 BLACK

- FKM VITON 40 OFF WHITE

- FKM 50. (DTD 5612 A) GRADE 50 SHORE

- FKM 50/55 (BRIGHT-RED) HEAT-STABILISED RUBBER

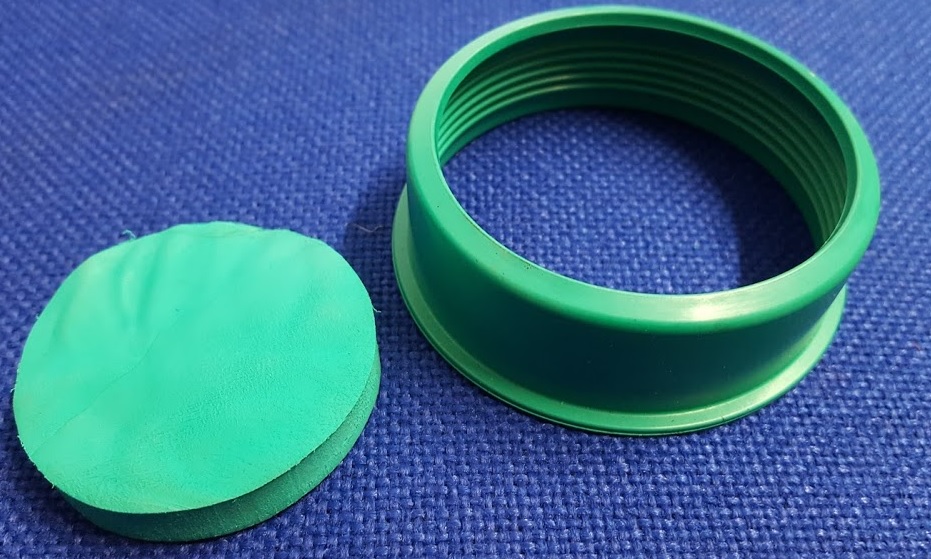

- FKM 60 GREEN FLUOROCARBON

- FKM 60. DTD 5543B GRADE 60

- FKM 60. DTD 5612A GRADE 60

- FKM 60 VITON GLT

- FKM 60 VITON GF

- FKM 70. DTD 5543B GRADE 70

- FKM 70 VITON GF GRADE

- FKM VITON GLT 70 GRADE

- FKM GLT 70 GRADE

- FKM 71-80 GRADE E (DTD 5543 A)

- FKM 75. AMS-R-83248C

- FKM 75. DTD 5543A GRADE E

- FKM 75. DTD 5612A GRADE 70 MILL-R-83248C (AMS-R-83248C)

- FKM 85 IRHD (BRIGHT-RED)

- FKM 90 FLUOROCARBON RUBBER

- FKM GRADE 80 FLUOROCARBON RUBBER

- FLOUREL/FLUOROCARBON 80 GREY

- FLUOROCARBON RUBBER AMS-R-83485, GRADE 70 – 80, BLACK

- FLUOROCARBON RUBBER, GRADE 60, COLOUR GREEN

- VITON 50 (DTD 5612 A)

- VITON 50 RED

- VITON 55/65 GREEN

- VITON 65/70 GREEN

- VITON 70 BLUE

- VITON 70 BROWN

- VITON B60

- VITON B70

- VITON B80

- VITON DTD 5543B 60 HARD

- VITON DTD 5612 A 50 HARD

- VITON DTD 5612A GRADE 80

- VITON E60C – 60/65 BLACK

- VITON GF 60

- VITON GF 70 BLACK

- VITON GF 70/75

- VITON GF 90

- VITON GF 90 BLACK

- VITON GLT 70

- VITON RUBBER TYPE GLT

All vitons® are the trade name of DuPont Performance Elastomers L.L.C.

(FVMQ) Fluorosilicone and fluoroelastomers

Stocked

- FLUOROSILICONE LS63

- FLUOROSILICONE AMS R 25988 GRADE 70 BLUE/RED

- FLUOROSILICONE 40 BLACK

- FLUOROSILICONE RUBBER GRD 50 GREEN

- FLUOROSILICONE RUBBER TO AMS-R-25988 CLASS 1 GRADE 60 TYPE 2 COLOUR BLUE

- FLUOROSILICONE RED

- FLUOROSILICONE (LS63) BLUE

- FLUOROSILICONE 60, BLACK

- FLUOROSILICONE 60 BLUE

- FLUOROSILICONE RED (LS63 RIO)

- FLUOROSILICONE R 25988 B GRADE 70 (AMS-R-25988) BLUE

- FLUOROSILICONE RUBBER, GRADE 80. BLUE

- FLUORO-SILICONE 80, WHITE. S.G. IS 1.7

- FLUOROSILICONE 60, BLACK. S.G. IS 1.45

- FLUROSILICONE LS 2860 VAROX TRANS

- FLUOROSILICONE 40 SHORE, BLACK, HEAT TEMPERED TO 250 DEG

- FLUOROSILICONE GRADE 80 BLUE

- FLUOROSILICONE (FSE7560-D1) EQUIVALENT TO LS63U

(HNBR) (H-NBR) Hydrogenated nitrile butadiene rubber

HNBR is known for its physical strength and retention of properties after long exposure to heat, oil and chemicals.

Stocked:

- HNBR 50 SHORE

- HNBR 50 (BASIC PROPERTIES)

- HNBR 50/60 SHORE

- HNBR 60 GRADE (HIGH TEAR) BLACK

- HNBR 60 SHORE

- HNBR 60 SHORE

- HNBR 70 GREEN

- HNBR 70 ZSC

- HNBR 70

- HNBR 70

- HNBR 70 BLUE FDA COMPLIANT

- HNBR 70 (BUTSER PAD BLEND)

- HNBR 80

- HNBR 80/85 BLUE

- HNBR 90, BLACK. S.G. OF 1.25

- HNBR GRADE 90, BLACK

(IIR) Butyl rubber

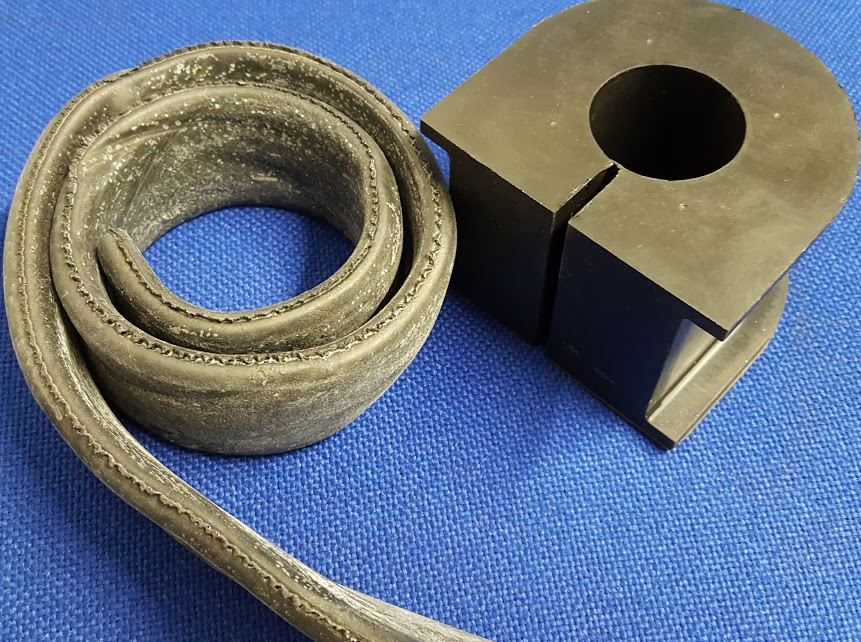

Butyl rubber is a synthetic rubber, a copolymer of isobutylene with isoprene. The abbreviation IIR stands for Isobutylene Isoprene Rubber

Stocked

- Butyl 40 (B 40)

- Butyl (Chloro-Butyl) Grade 40, (Off White)

- Butyl 50 to BS3227 (B50) Black

- Butyl 50 (Chloro) to BS 3227:2003 Grade B50

- Butyl 60

- Butyl 60 (BS3227) (B60) (56-65)

- Butyl 60 (Chloro-Butyl) Black to Def Stan 93-86

- Buytl 60 (Bromo-Butyl) BS3227:2003 Grade B60

Loaded Rubbers and Silicones

Butser Rubber can supply ‘loaded’ materials for use on specialist applications. The rubber compound can be mixed with a range of different material fibers and metals to provide different properties.

Our specialist range used to increase strength and modulus includes:

- Carbon Fiber and Rubber Compound.

- Kevlar Fiber and Rubber Compound.

- Normex Fiber and Rubber Compound.

- Cotton Fiber and Rubber Compound.

We can also provide materials to increase electrical conductivity, thermal conductivity or thermal resistance and weight.

-

- Iron loaded Rubber Compound.

-

- Tungsten loaded Rubber Compound.

-

- Silver loaded Silicone.

-

- Silver Coated Aluminium Rubber Compound.

-

- Aluminium loaded Rubber Compound.

-

- Steel loaded Nitrile Rubber.

- Makrolon loaded Rubber or Silicone Compound.

Nitto Sponges: EE1010 & Nitto EPT-Sealer No.686

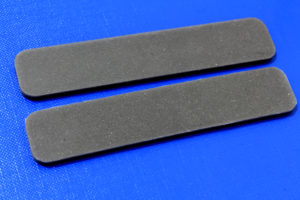

Butser Rubber can: Laser Cut, Die Cut & Fabricate: Strips, Seals, Sheet & NVH components in a selection of Nitto EE1010 & 686 Grades.

Stocked:

Nitto EE1010 in 3 mm

Nitto EE1010 in 5 mm

Nitto EE1010 in 10 mm

Nitto EE1010 in 15 mm

Nitto EE1010 in 20 mm

Nitto EE1010 in 25 mm

and

Nitto 686 in 10mm

Both Nitto EE1010 and Nitto 686 are semi-closed cell structure EPDM Foams with a flexible open cell type providing excellent sealing capabilities of closed cell types (after compression). EE1010 is a unique foam laminated with an acrylic-based double-coated adhesive tape to seal (complex) gaps against: Water, Wind, Dust, Noise and Heat.

(NBR) Nitrile rubber

NBR, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene.

Stocked:

- NITRILE 40/45 SHORE (GREY FOOD QUALITY)

- NITRILE 60 SHORE (WHITE FOOD QUALITY) NON-STAINING

- NITRILE BS2751 BA40 36-45 IRHD

- NITRILE BA60 (NBR60) BS 2751

- NITRILE (BS2751) BA80 76-85 IRHD

- NITRILE 40/45 RED

- NITRILE 65/75 BRIGHT RED

- NITRILE 70 IRHD (LIGHT-GREY)

- NITRILE DTD 5595A (GRD-70)

- NITRILE RUBBER (BS2751 BA60) 56-65 HARDNESS

- NITRILE RUBBER (BS2751 BA70) 66-75 HARDNESS

- NITRILE PSLC/6 GRADE.D

- NITRILE 70 Shore A

- NBR 40/45 RED

- NBR 40/45 (GREY F/Q)

- NBR 50/55 94 A

- NBR 55 DTD 5509/D

- NBR 55/65 F.Q.WHITE

- NBR 60 DTD 5594 GR 60

- NBR 60 DTD 5595 A

- NBR 60 (FQ) WHITE

- NBR 70 (BA70) BS 2751:2001 (BA)

- NBR 70 BLACK (FQ)

- NBR 70 DTD 5594A GRADE 70

- NBR 75/85 PEROXIDE CURE

- NBR 80

- NBR 80/90 (5595A)

- NBR 90 (BA 90) NITRILE

- NBR 90 DTD 5594A GRADE 90

- NBR/HNBR 60 (GOOD TEAR)

- NBR/PVC 45 (BLUE)

- NBR/PVC 60 (BLUE)

- LOW NITRILE (LOW NBR) 60 BLACK

- LOW NITRILE (LOW NBR) 70

Natural Rubber

(NR) Natural Rubber

Natural Rubber’s elasticity makes it suitable for various shock absorber and suspension applications including mountings designed to reduce vibration. Being relatively impermeable to gases, Natural rubber is used in applications such as: Air hoses, Vacuum tubes, and balloons.

Stocked:

- HSN401 GUM STOCK NATURAL RUBBER BLACK

- NATURAL GUM MOULDING GRADE

- NATURAL RUBBER GUM (BROWN COLOUR)

- NR 30/35 BLACK.

- NR 40 BLACK

- NR 40 HIGH ELONGATION

- NR 40 GREY F/Q

- NR 40 LIGHT GREEN

- NR 40 LIGHT GREY

- NR 40 OLIVE GREEN

- NR 40. BS 1154. (Z 40)

- NR 50 (Z 50)

- NR 50 BLACK

- NR 55. BS1154:2003 Y3 WHITE

- NR 60 (Z60)

- NR 60 (YELLOW)

- NR 70 (ARE 1070)

- NR 70 F/Q WHITE

- NR 70 GREY HIGH TEAR/WEAR NERO

- NR 70. BS 1154. (Z 70)

- NR 70 +/-3IRHD

- NATURAL RUBBER (Z 70) BLACK.

- NATURAL RUBBER (NR 70) (NRQX 70) TO DEF STAN 93-30 BLACK

- NATURAL RUBBER (NRQX 40) TO DEF STAN 93-30 BLACK 36/45 HQ

- NATURAL RUBBER (NRQX 70) TO DEF STAN 93-30 BLACK IRHD 66-75

- NATURAL RUBBER 60 RED. S.G. IS 1.38

- NATURAL RUBBER 60 WHITE. S.G. IS 1.42

- NATURAL RUBBER BS1154 Z60 IRHD 56-65 BLACK

- NATURAL RUBBER TO DEF STAN 93-30 EQUIVALENT GRADE QX 40 BLUE

- NATURAL RUBBER Z40 TO BS 1154 IRHD 36-45 BLACK

- NATURAL RUBBER Z90 TO BS1154:2003

- NR 75.

- NR 80. (Z 80)

- NR 85

- NR 90 (STYRENE RESIN) EQUIVALENT TO BR15

- NAT/NEO 50-60

(PCR) PCR rubber

Stocked:

- PCR 40 ‘SHORE A’

- PCR 55 SHORE YELLOW NEO

- PCR 60 ‘SHORE A’ BLACK HIGH ELONGATION

- PCR 60 IRHD BLACK

- PCR 60 IRHD (C60)

- PCR 60 IRHD YELLOW

- PCR 60/70 IRHD BLACK

- PCR 70 IRHD RED

- PCR 75/80 IRHD

- PCR 78/83 (CONDUCTIVE)

- PCR GOOD FLEX 80 SHORE

- PCR 80 SHORE (CONDUCTIVE)

- PCR 70 BLACK WITH GRAPHITE

- PCR BS2752:2003 C80 BLACK

(PUR) Polyurethane rubber (Poly-U rubbers)

Stocked:

- POLYURETHANE 50 BLACK

- POLYURETHANE 50 WASHED OUT BLUE

- POLYURETHANE 75 GREY

- POLYURETHANE 95

- POLYURETHANE 95 BLACK.

- POLYURETHANE -70 GREEN BR/FP/04/08/034

- POLYURETHANE 70 SAND STONE YELLOW

- POLYURETHANE 75 BLACK

- POLYURETHANE 95 BLUE

- POLYURETHANE POLY U 95 PILLAR BOX RED

- POLYURETHANE 60 (BLUE)

- POLYURETHANE 70 (GREEN)

- POLYURETHANE 85, BLACK

- POLYURETHANE GRD 70/75 BLACK.

- POLYURETHANE NOM HARDNESS 55 SHORE D BLACK (VERY HIGH HARDNESS)

- POLYURETHANE RUBBER 90.

- POLYU 70 GREY MOSS

- POLY-U 70 RED

- POLY-U 83 GREY

- POLY-U 95 GREY

- POLY-U 70 BLUE

- POLY-U 90.

- PU 60 BLACK

- PU 70 GREEN

SBR Rubber

(SBR) Styrene Butadiene Rubber

SBR rubbers are synthetic rubbers derived from styrene and butadiene. These materials have good abrasion resistance and good ageing stability when protected by additives. About 50% of car tyres are made from various types of SBR.

Stocked:

-

- SBR Rubber Grade 40 Black

- SBR Rubber Grade 50 Bright Red

- SBR Rubber Grade 50 Black

- SBR Rubber Grade 60 Black

- SBR Rubber Grade 60 White

- SBR Rubber Grade 60 Off White

- SBR Rubber Grade 60 Bright Red

- SBR Rubber Grade 70 Black

- SBR Rubber Grade 80 Black

- SBR/BR 70 Roller Grade

- SBR/Natural Rubber Blend, Grade 50, Off-White.

- SBR/Natural Rubber Blend, Grade 60, Off-White.

- SBR/Natural Rubber Blend, Grade 70, Black.

- SBR/Natural Rubber Blend, Grade 70, Red.

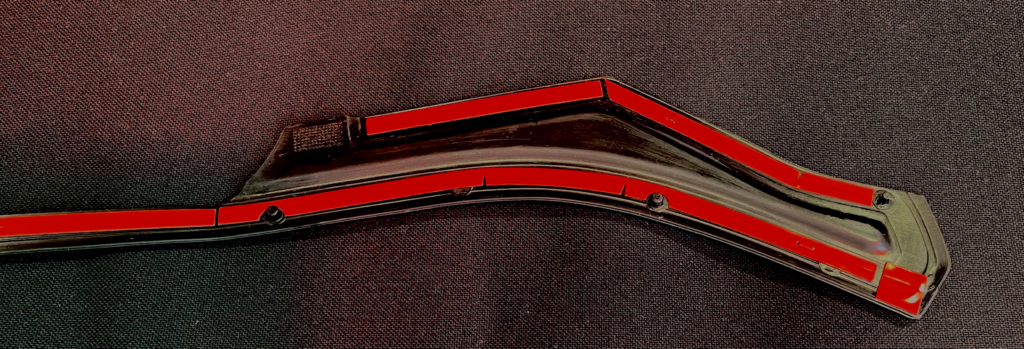

Slip coating

Resilon coatings are specifically designed for the automotive market, providing excellent release, noise suppression, protection from weathering, controlled friction and chemical and abrasion resistance compared to uncoated parts. Coatings are available in water- or solvent-borne formulas and are ideal for all forms of rubber, plastic and fabric used in today’s automobiles.

Benefits:

- Abrasion protection

- Excellent release

- UV protection

- Low coeffcient of friction

- Noise reduction

- Chemical resistance

Stocked Resilon slip coats include:

- Resilon 2020/D8808

- Resilon 2020/G3737

- Resilon 2020/G8002

- Resilon 2020/G8808

- Resilon 2020/G9801

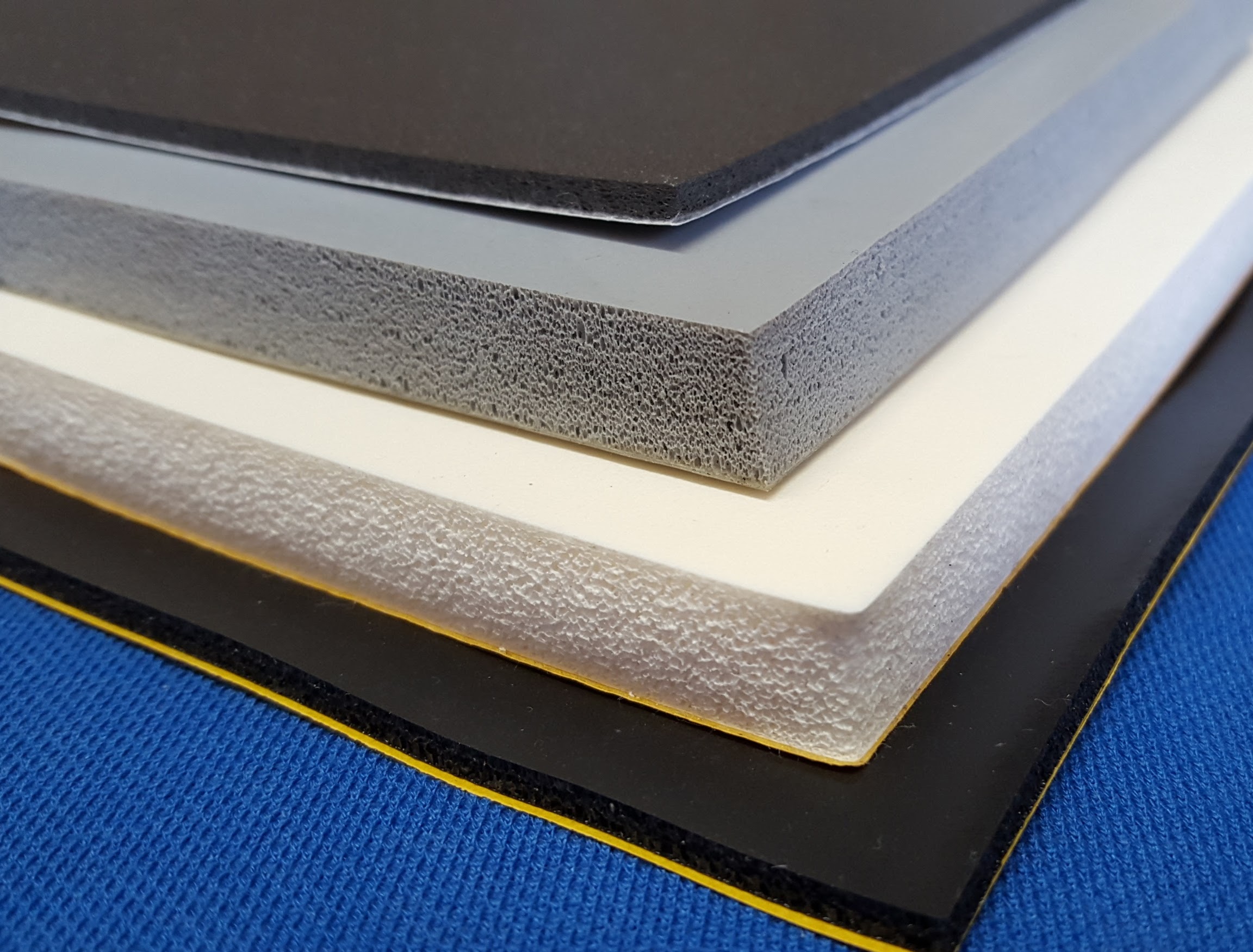

Silicone Rubber Sheet

Silicone Sponge Sheet

Butser Rubber supply main grades of silicone sponge sheeting ranging from 1.5 mm thick to 30.0 mm thick, our most common and standard materials can be seen below.

Standard Silicone Sponge Density:

The standard sponges are: White, Black (Dark Grey) and Red Iron Oxide. There are 4 standard densities off the shelf: Of these, the Sil16 (250KG/m3) is the most available and common grade.

Code: SIL10 = 10 lb/ft3 (200Kg/m3) (SE510)

Code: SIL16 = 16 lb/ft3 (250Kg/m3) (SE515)

Code: SIL24 = 24 lb/ft3 (400Kg/m3) (SE524)

Code: SIL33 = 33 lb/ft3 (500Kg/m3) (SE533)

Standard Sponge Thicknesses:

(Based on Sil16. Please esquire for stock availability if you require a different density)

1.5 ±0.50

2.00 ±0.50

2.50 ±0.50

3.00 ±0.50

4.00 ±0.50

5.00 ±0.50

6.00 ±0.75

7.00 ±0.75

8.00 ±0.75

10.00 ±0.80

12.00 ±1.00

15.00 ±1.50

20.00 ±2.00

25.00 ±2.50

We can supply these silicone sponge materials either as a standard sheet and roll. Widths of 1 meter and lengths of 1 meter, 5 meter or 10 meter, or we can cut the sheeting into gaskets and custom sponge seals to your design with our in-house gasket cutting machines.

These grades of silicone sponge sheet offer excellent compression properties and can be used as gasket and seals where the sealing surface is not very smooth or even.

Water absorption values are less than 1%, providing excellent sealing properties from water and dust.

Used for sealing application on: HVAC, Aerospace Filtration, Automotive Filtration and air ducting, Air Box covers and lids.

Silicone Rubbers - VQM

(VMQ) Silicone Rubber (Moulding Grades)

Silicone rubber is an elastomer composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone has excellent high temperature properties and can be manufactured to food quality grades.

Stocked:

- Silicone Black 10-20 Shore A

- Silicone Grey 10-20 Shore A

- Silicone Blue 10-20 Shore A

- Silicone Red 10-20 Shore A

- Silicone Translucent 20

- Silicone Grey 20 Shore / IRHD

- Silicone Black 20 Shore / IRHD

- Silicone Rubber 20 IRHD Red Oxide (High Temperature)

- Silicone 30/35 Blue

- Silicone 35 Translucent

- Silicone 35/40 Black

- Silicone 40 High Temp Grade

- Silicone 40 Automotive Grade.

- Silicone 40 High Tear Strength Grade

- Silicone 40 Rio Red to meet AMS 3301

- Silicone 40 High Tear, Blue

- Silicone 40 High Temperature Red

- Silicone Clear 40 (Translucent)

- Silicone 40 Red Oxide

- Silicone 40 Red Rio

- Silicone 50 Black High Tear

- Silicone 50 DTD 5531a. Grade 50 (White)

- Silicone 50 H.S Grey

- Silicone 50 Translucent

- Silicone Grade.50 (Food-Quality Colour Blue)

- Silicone 50 to meet AMS3301 (RIO)

- Silicone 50 FDA and Metal Detectable Grade – Blue

- Silicone 50 White (DTD 5531)

- Silicone 50 (White Food Quality)

- Silicone Rubber Lt50-02 (DCBP, Black)

- Silicone Pink Grade 50

- Silicone 50/55 White Translucent

- Silicone 50/60 Platinum-Cure, Red Iron Oxide

- Silicone 50/60 Ri0 Red

- Silicone Grade 60 Colour Blue

- Silicone 60 Platinum-Cure (Blue)

- Silicone 60 High Tear (Black)

- Silicone 60 High Tear (Light Grey)

- Silicone 60 Platinum Cure Red

- Silicone 60 Red Rio

- Silicone 60 Blue Platinum Cured

- Silicone Grade 60 Green

- Silicone 60 Rio. (DTD 5582 A)

- Silicone 60 Translucent High Tear

- Silicone 60 White (DTD 5531 A) Grade 60

- Silicone 60 Yellow (High-Tear)

- Silicone 60 FDA and Metal Detectable Grade – Blue

- Silicone 70 Blue DTD 5582

- Silicone 70 Drab Olive Green

- Silicone 70 DTD 5531 White

- Silicone 70 DTD 5531 White

- Silicone 70 Red Iron Oxide DTD 5582A

- Silicone 70 Trans Translucent

- Silicone 70 FDA Blue and Metal Detectable

- Silicone 80 High Tear Black

- Silicone 80 Transparent

- Silicone 85 Shore (Black Non-Marking)

- Silicone (DTD 5531 A) Grade 70

- Silicone (DTD 5582 A) Grade 60

- Silicone Grade 20 Red

- Silicone Grade 50 Rio

- Silicone Grade 60 Dark Grey Fire Retardant

- Silicone Grey 50

- Silicone High Tear 60 (Red Iron Oxide) DTD 5615 A

- Silicone Rio 70

- Silicone Rubber GP Grade 50 Black (Br 15)

- Silicone Rubber High Tear, Trans Grade 60

- Silicone Rubber Oil Resistant DTD 5582 A Grade 60 Black

- Silicone Rubber Platinum Cured Grade 60 Blue

- Silicone Rubber, Platinum Cure Grade 40 Yellow

- Silicone White To DTD 5531a Grade 70

- White Silicone DTD 5531 A Grade 80 A

- Silicone 75 Translucent To ASTM D2000 M706 Z1=Hardness 70-80 Shore A.

3M Tapes

We can supply rubber mouldings Including: EPDM, Neoprene and Natural rubbers with a range of 3M products. We can: prep, prime and back mouldings in house with a selection of VHBs, Transfer liners, Acrylic tapes. All of these can be done with a selection of 3M primers and promotors. Giving us the ability to add value to the parts as well as absorbing many stages in the supply chain.

Stocked 3M Products –

Tapes

- 3M 9485

- 3M 9482

- 3M PT1100

- 3M PT1500

- 3M PX5000

Primers

- 3M 83

- 3M 94

- 3M Universal primer VHB

- 3M 4298

- 3M VHB Surface Cleaners

Rubber Material Properties

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| Cost Factor | 1 | 1 | 2 | 2 | 2 | 6 | 15 | 40 |

| Hardness Range (Shore A) | 30 – 90° | 40 – 95° | 30 – 85° | 30 – 90° | 40 – 100° | 40 – 80° | 50 – 95° | 40 – 80° |

| Colours | Full Range | Full Range | Limited | Full Range | Limited | Limited | Limited | Limited |

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| Maximum Continuous | 75° | 85° | 130° | 95° | 100° | 205° | 205° | 180° |

| Maximum Intermittent | 105° | 115° | 150° | 125° | 130° | 300° | 300° | 200° |

| Minimum Temperature | -60° | -55° | -50° | -40° | -20° | -60° | -20° | -60° |

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| Oxidation | Fair | Fair | Excellent | Very Good | Good | Excellent | Excellent | Excellent |

| Ozone & Weathering | Poor | Poor | Excellent | Very Good | Fair | Excellent | Excellent | Excellent |

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| ASTM Oil No. 1 @ 20° | Poor | Poor | Fair | Excellent | Excellent | Excellent | Excellent | Excellent |

| ASTM Oil No. 1 @ 100° | Poor | Poor | Poor | Good | Good | Good | Excellent | Excellent |

| ASTM Oil No. 3 @ 20° | Poor | Poor | Poor | Good | Excellent | Good | Excellent | Excellent |

| ASTM Oil No. 3 @ 100° | Poor | Poor | Poor | Fair | Good | Fair | Excellent | Excellent |

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| ASTM Fuel B @ 40° | Poor | Poor | Poor | Poor | Fair | Poor | Excellent | Fair |

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| Alcohol | Good | Good | Good | Good | Good | Good | Good | Good |

| Acetone | Fair | Fair | Good | Fair | Poor | Fair | Unsuitable | Unsuitable |

| Benzene | Poor | Poor | Poor | Poor | Poor | Poor | Good | Good |

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| Acids | Fair | Fair | Good | Good | Good | Fair | Excellent | Good |

| Bases | Good | Good | Good | Fair | Fair | Fair | Good | Fair |

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| Physical Strength | Excellent | Good | Good | Good | Good | Poor | Good | Poor |

| Compression Set | Good | Good | Good | Fair | Good | Good | Good | Good |

| Tear & Abrasion Resistance | Excellent | Good | Good | Good | Good | Poor | Good | Poor |

| Resilience | Excellent | Good | Very Good | Very Good | Good | Good | Fair | Fair |

| Full name | Natural Rubber | Styrene-butadiene rubber | Ethylene Propylene Diene Monomer | Neoprene/ chloroprene | Nitrile | Silicone | Viton / Fluorocarbon | Fluorosilicone |

|---|---|---|---|---|---|---|---|---|

| Code | NR | SBR | EPDM | CR | NBR | VMQ/SI | FPM/FKM | FVMQ |

| Permeability To Gases | Poor | Low | Low | Low | Low | Low | Very Low | Low |

| Electrical Strength | Excellent | Excellent | Excellent | Good | Poor | Excellent | Good | Excellent |

| Flame Resistance | Poor | Poor | Poor | Self – Extinguish | Poor | Good | Self – Extinguish | Self – Extinguish |

| Water Resistance | Very Good | Good | Excellent | Good | Good | Good | Good | Good |

Blending silicone rubber

Blending process prior to injection moulding.