Aerospace

Butser Rubber supply critical rubber components for the Aerospace sector and have done for over 30 years. Fast developments in end of life application have pushed Butser to continuously improve processes and products.

Our parts can be found on nearly all commercial aircraft operating today, including the Airbus A319, A320, A340 and the A380. No matter what the function or service you are after, Butser is here to supply you quality rubber mouldings to the spec you need.

Examples of area’s Butser have been involved in:

Aircraft restoration rubber mouldings Remanufacture of pattern parts Battle of Britain Memorial rubber components Aerospace components Commercial airline rubber seals

Producing FAIR’s to industry standard AS9102 with traceability to raw material source. We are able to inspect components using non contact video edge detection to fulfil MS and SPC requirements upon request.

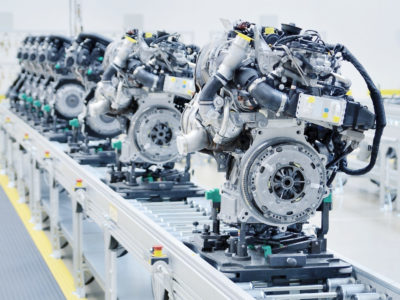

Automotive

Butser Rubber proudly supply a host of custom rubber mouldings for the Automotive industry. We have worked on a number of projects over our 30 years in industry including those with specialist applications such as mounting electronics on exhausts in high temperature environments.

We can supply PPAP Level 3 documentation to include:

Part Submission Warrant (PSW) Component Quality History (CQH) Pre-Failure Mode Analysis (PFMEA) Control Quality Planning (CQP) Material Testing Ballooned Drawing Flow Chart Control Plans CMM Profile Report

We have the technology to mark parts either through the tool of as a post-process (this will incur additional cost).

Defence

Butser Rubber has been heavily involved in the defence industry for over 30 years. This includes working with and directly supplying the MOD and private defence companies in the UK, the U.S. and Europe. We can supply rubber and rubber fabrications to many Defence Standards including natural to NRQX. If the standard you require isn’t here, why not call us to see if we can supply it for you?

Our involvement with the defence industry goes beyond manufacturing rubber mouldings. Butser Rubber can be involved in the prototyping, production and final assembly of kit stages. (Ask for details on your project).

Our in-house knowledge and range of machines allows us to carry out many operations of a component build, under one roof.

Using our award winning 123MRP factory operating system, setting up multiple drops, Kanban or supplier schedules can be handled with ease.

Agriculture

Butser Rubber has close links to the agricultural industry. We have first-hand experience on a number of machines and systems used. From milk parlours to bailers we have knowledge that will help you in the optimisation of your part.

Renewables

Butser Rubber are now supplying to the renewables market. We can manufacture rubber washers, grommets or gaskets with high compression capabilities that help support wind turbines. Whether it be for a moving component that requires high tear resistance rubber parts or for a stationary component in need of rubber with good weathering properties we can help guide you to the right choice material.

Health Care

Butser Rubber are becoming more involved in the health care industry, manufacturing sub components for hospital equipment to a number of suppliers. We are happy to be involved in the prototyping of your design to help benefit better manufacturing suitability.

Our facilities allow us to manufacture medical grade rubber mouldings for use on a wide range of applications

Motorsport

Butser Rubber made its first ‘Formula One’ component back in 1979 and has not looked back since. Now we supply components, sealing, anti vibration and flexible solutions to all the Formula one teams, either directly or indirectly through team engine builders and transmission builders.

Working with Formula One for many years has given us a very deep understanding of the motor sport industry. Now we build key components for cars in The ‘World Rally Championship’, ‘British GT Series’, ‘Formula Nippon’, ‘GP’ and ‘Le Mans 24’. That is just to list a few, as our components can be found in many of the single seater race car championships.

Restorations & Customisation

Through The Autosport show we are now very much involved in classic and vintage car rebuilds from collectors to restoration. This includes one off components for cars competing at the Goodwood Festival of Speed through to complete customised rubber components including bushes, suspension cones and gasket kits, for cult and unique rally, track and road cars.

We are very happy to look at original components and recommend materials for improved end use application.

Filtration Systems

Butser Rubber provides a world class custom rubber moulding service for the filtration system industry. We have long history of providing filtration components such as gaskets and seals to high profile clients. Working from your initial designs on paper or CAD we will guide you through the manufacturing process to ensure quick lead times and a competitive price.

Our investment driven manufacturing facilities allow us to produce rubber components from a one off prototype to a mass-production run.

We can meet industry standards including ISO 9001 with full traceability through our award winning 123Insight software.

Marine

With over 12 years experience within the Marine industry Butser has become key suppliers to sealing solutions for warships. Within the marine environment we have experience manufacturing sub-sea-sensors in Neoprene and EPDM. Our parts are well recognised for quality and reliability within their environments which is due to the right material choice being made at the beginning.

Railways

We have been manufacturing rubber components for the rail industry for 20 years. We have supplied protective caps for signal stop signs and water exclusion caps to weather proof safety signs on the line among other products for line safety equipment.

General Industry

Butser Rubber have experience manufacturing rubber grommets for electrical insulation and waterproofing seals for telephone exchange boxes to name a few. We manufacture standard rubber components such as EPDM grommets or Polyethylene washers to all areas of industry as well as specialist applications based on your specification and material needs.